| Type: | Concrete Block Making Plant |

| Characteristic: | Production of different types of concrete wall blocks |

| Model: | QT4-20 |

1. QT4-20 semi Automatic block forming machine Main technical parameters:

| Dimension Of block making machine | 2400×1600×2100mm | Motor Power | 11.75KW |

| Mould Area | 550×850mm | Vibration Force | 50KN |

| Working cycle | 26S | Concrete mixer model | JQ350 |

| The Size Of The Pallet | 850×550×25mm | Water Consumption | 4T/Every Day |

| Weight Of The block making machine | 3500kgs | Voltage | Customized |

2. QT4-20 semi Automatic block forming machine Production capacity:

|

Size(LxWxH) |

Pcs/Mould | Pcs/ Hr | Pcs/ 8 Hr |

| 400X100X200 | 8 | 800 | 6400 |

| 400X150X200 | 5 | 500 | 4000 |

| 400X200X200 | 4 | 400 | 3200 |

| We can provide different sizes mould as you request. | |||

3. How does Automatic Block Making Machine work?

1. Cement silo and screw conveyor: The cement silo is used to store the bulk cement which is used for concrete. The screw conveyor is connect with the cement silo and concrete mixer to transfer the cement into the concrete mixer. These two parts are optional parts. You can get them at local market or purchase them from us together with our block making machine;

2. Aggregate batching machine: It consists of two or three storage bins and one weighing bin. It also contains belt conveyers which is used to convey aggregate and sand from the storage bins to weighing bin. Batching and weighing is controlled by PLC.

3. Concrete Mixer: All the ingredients are mixed in this concrete mixer. Mixing time and speed is controlled by PLC. The water pump which is controlled by time relay adds water to the mixer automatically;

4. Belt conveyor: after the concrete is ready, it will be discharged to this belt conveyor, the belt conveyor will transfer the concrete to the concrete block machine;

5. Block making machine: This is key part of the production line. It presses the concrete to block. It can be used to make various hollow block, solid brick, paver brick and kerbstone by changing different sizes moulds;

6. Stacker: Stacker is used to stack the blocks automatically, which is high-efficient and labor saving.

7. After the above procedures, the blocks will be transported to the storage yard for drying.

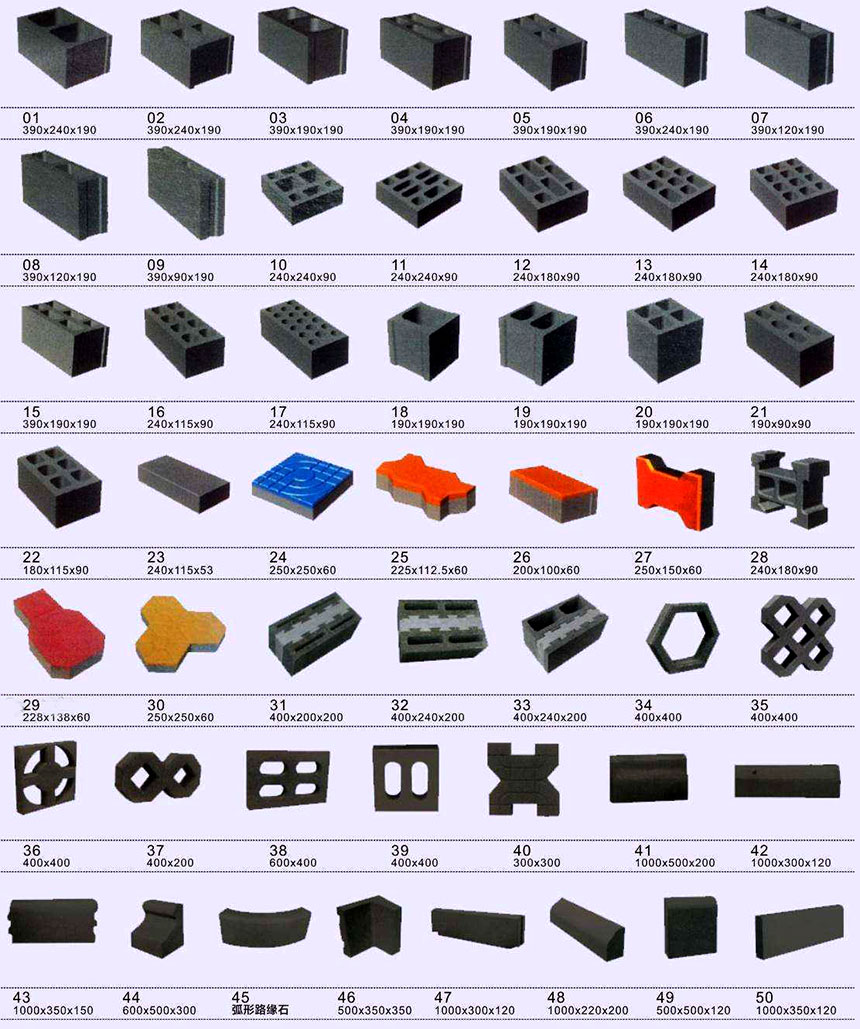

4. Block and Brick Models:

automatic concrete block making machine

block maker machine

fly ash brick machine manufacturers

coir pith block making machine

concrete pump supply

planetary concrete mixer

paving block making machine

coir pith block making machine

Concrete Batching Plant

Indonesia

Concrete Batching Plant

Viet Nam

Concrete Batching Plant

Indonesia